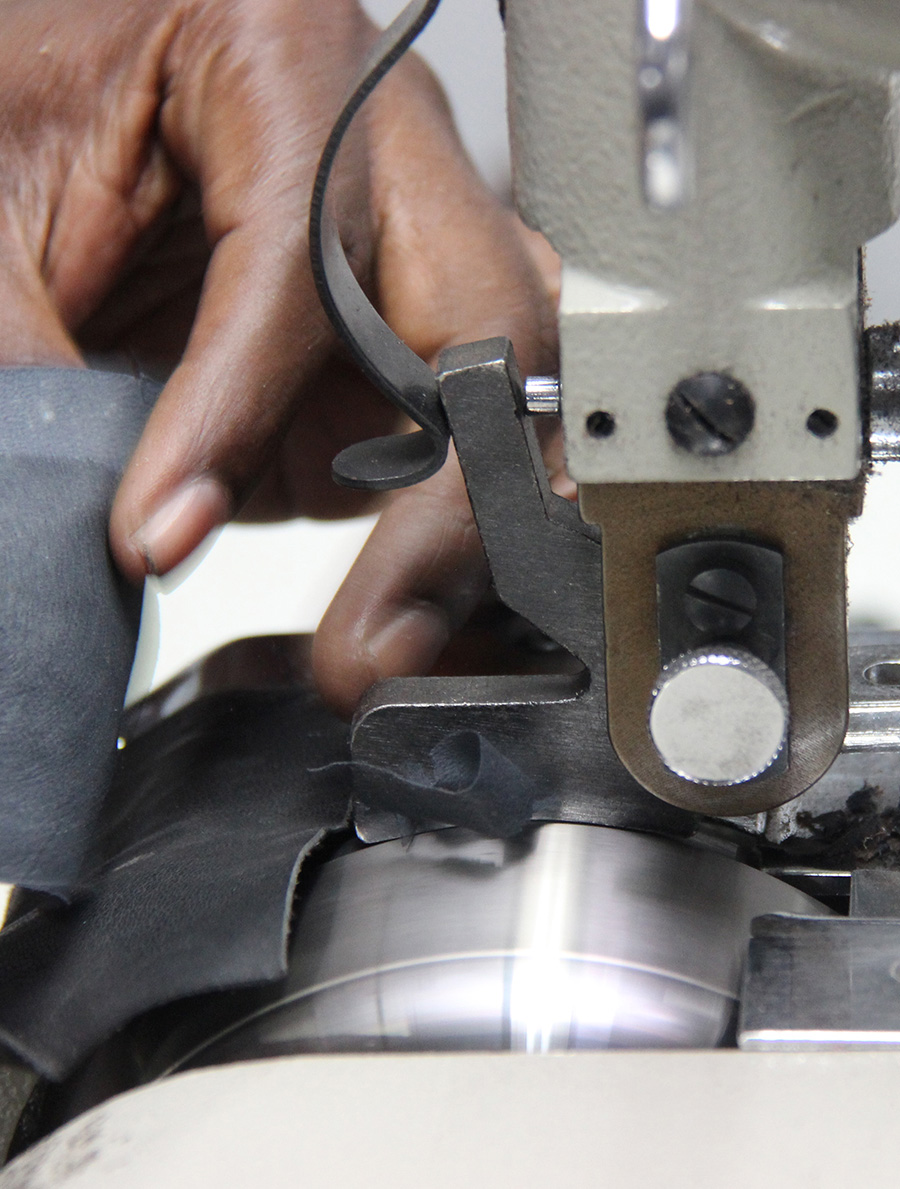

Our Factories which are Located in Chennai (3 units) and in Kolkotta (1 unit) are equipped with latest machinery in Cutting, Sewing etc., and Skilled Work force capable of producing all types of Leather Garments as per buyer requirements. We currently have a production capacity of over 2 lakh Jackets per annum and we are in the process of scaling it up to produce 3 lakhs pcs by 2016. Our production units are ISO 8000 audited /certified and we follow the industrial standards.

We have In-house washing units manned with Experienced and Qualified Leather Technicians besides the Skilled, Dedicated and Experienced Workforce. We do washes like Enzyme wash, Stone wash, Staining etc as per the buyers standard and our expertise is in the Excellent HAND FEEL we achieve on our garments. Our trims and accessories for the Jackets are sourced from the Best reputed local suppliers as well as from the reputed and nominated overseas suppliers. We do not Compromise neither on the Quality of Our products and workmanship nor on the raw materials and trims used for our products. The Leather we source for our Jackets and our Other Leather products are from the best Tanneries in India and also from reputed tanneries across the world. We use Sheep skins, Goat Suede, Nubuck, Buff leathers etc with various finishes and also articles like Foil Leather, Printed leather, Stretch Leather etc for our products.

We have tanneries in and around Chennai with qualified technicians to monitor and ensure we achieve the quality and finish as Expected by our clients.

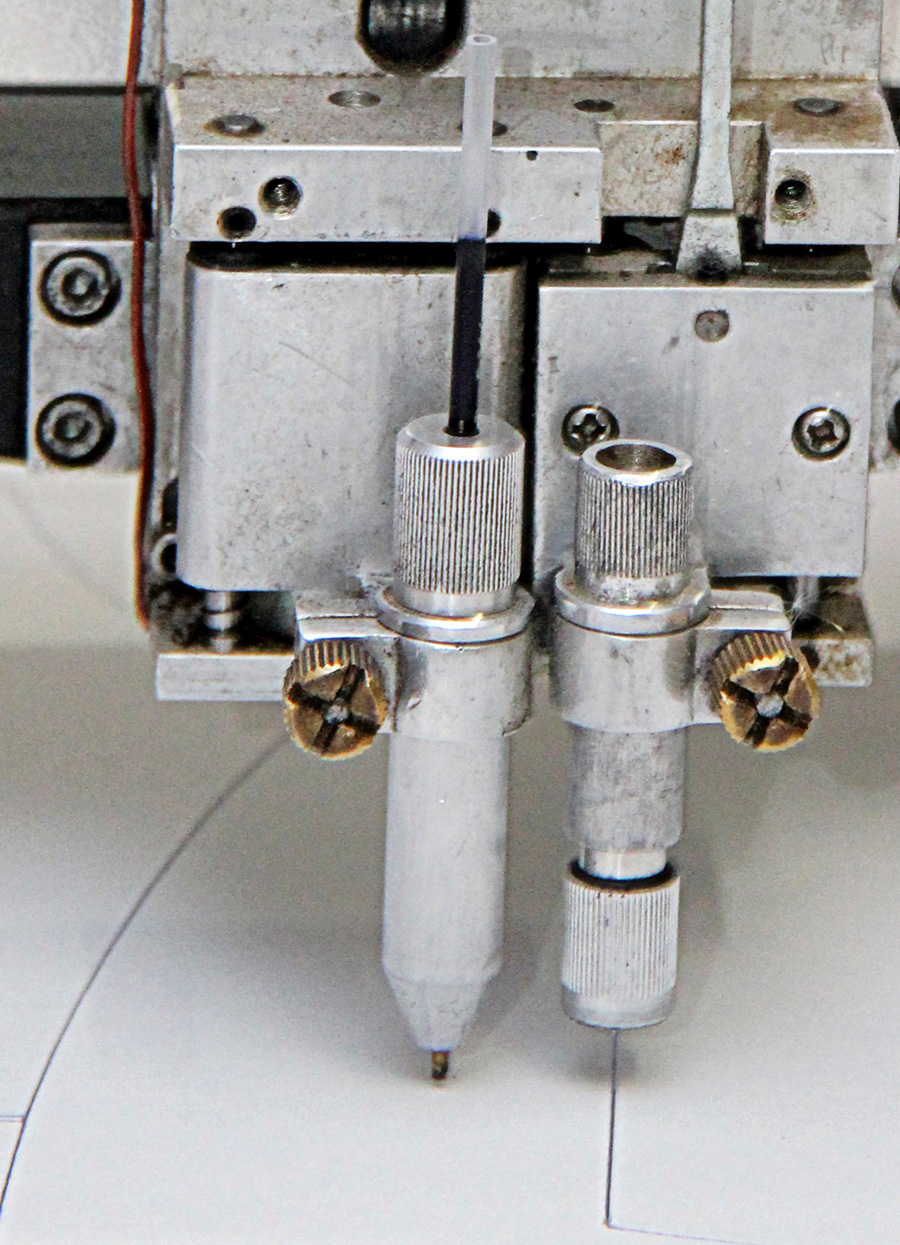

Our pattern department (CAD) is equipped with the latest computerized pattern machines, manned by qualified technicians to ensure that the fit and specifications are exactly as per buyers requirement. We also have a dedicated sampling section to ensure that samples are turned around in quick time.

Our efficient Merchandising team will ensure customer satisfaction through Sampling of Merchandise to specifications. Sending out Costings for product developments, Communicating and coordinating, with buyer regularly sending sample status, production status, shipping information etc., Keeping the buyer fully informed about the progress and status at every stage, maintaining a proactive approach to ensure on-time delivery of the shipments.

Our Internal Quality Assurance teams are very experienced and well versed with the AQL standards and will ensure that the buyers standards are met. We have a dedicated team as well for ensuring the finished products are packed and shipped as per the buyers Standards. We aim to deliver defect-free garments of quality and as per Buyers schedule. We look forward to fulfilling our promises and your expectations and doing a meaning business with your Esteemed organization.